Pellet is a type of solid fuel made from compressed organic material, such as wood, agricultural residues, or industrial waste. Pellet has many advantages over fossil fuels, such as lower greenhouse gas emissions, higher energy density, and easier storage and transportation. Pellet can be used for heating, cooking, and power generation in various applications, such as pellet stoves, furnaces, boilers, and co-firing plants. In this article, I will explore the history, roots, interesting facts, current use, production, and future of pellet as a sustainable and renewable energy source.

History and Roots of Pellet

The use of biomass pellets for energy dates back to the 1970s when alternatives to fossil fuels were sought in the wake of the energy crises of the decade. The first commercial pellet mills were imported from England to the United States in 1928, but they were mainly used for animal feed production. The first pellet stoves were developed in the 1980s in Europe and North America, and they gained popularity as a convenient and efficient way of heating homes with renewable fuel. The demand for pellet heating increased further in the 2000s as the price of fossil fuels surged and the awareness of climate change grew. The wood pellet sector also expanded into the industrial market, where large-scale power plants started to co-fire or replace coal with wood pellets to reduce their carbon footprint and comply with environmental regulations.

According to the International Energy Agency (IEA), wood pellet production has more than doubled between 2006 and 2010 to over 14 million tons. In 2019, the global wood pellet market was valued at $8.6 billion USD and is expected to reach $15.9 billion USD by 2027, growing at a compound annual growth rate (CAGR) of 8.6 per cent. The major drivers for this growth are the increasing demand for renewable energy sources, the rising environmental concerns, and the supportive government policies and incentives.

Interesting Facts about Pellet

– Pellet is made from biomass that would otherwise be wasted or burned, such as sawdust, wood chips, bark, straw, husk, or shells. Pellet production helps to reduce waste disposal costs and greenhouse gas emissions.

– Pellet has a high energy density of about 18 MJ/kg, which is comparable to coal (24 MJ/kg) and higher than firewood (15 MJ/kg). Pellet also has a low moisture content (below 10 per cent) that allows it to burn with a high combustion efficiency of over 90 per cent.

– Pellet is easy to store and transport because of its regular shape and small size. Pellet can be delivered by truck, train, or ship to various destinations. Pellet can also be blown from a tanker to a storage bunker or silo on a customer’s premises.

– Pellet is carbon neutral because it releases the same amount of carbon dioxide that was absorbed by the biomass during its growth. Pellet also helps to reduce deforestation by using wood residues instead of cutting down trees for fuel.

– Pellet can be used in various applications, such as residential heating, commercial heating, district heating, industrial power generation, and co-firing with coal or natural gas. Pellet can also be used for cooking in developing countries where access to electricity or gas is limited.

Current Use of Pellet

The current use of pellet varies by region and market segment. According to the IEA Bioenergy Task 40 report on Global Wood Pellet Industry and Trade Study 2017, Europe is the largest consumer of wood pellets in the world, accounting for about 75 per cent of the global demand in 2016. The main use of wood pellets in Europe is for residential heating (47 per cent), followed by district heating (25 per cent), power generation (19 per cent), and commercial heating (9 per cent). The main drivers for wood pellet consumption in Europe are the high prices of fossil fuels, the ambitious renewable energy targets, and the supportive policies and subsidies.

North America is the second largest consumer of wood pellets in the world, accounting for about 11 per cent of the global demand in 2016. The main use of wood pellets in North America is for residential heating (67 per cent), followed by power generation (23 per cent), commercial heating (7 per cent), and district heating (3 per cent). The main drivers for wood pellet consumption in North America are the low prices of wood pellets compared to other heating fuels, the convenience and comfort of pellet stoves and furnaces, and the environmental benefits of using renewable fuel.

Asia is the third largest consumer of wood pellets in the world, accounting for about 9 per cent of the global demand in 2016. The main use of wood pellets in Asia is for power generation (77 per cent), followed by residential heating (12 per cent), commercial heating (7 per cent), and district heating (4 per cent). The main drivers for wood pellet consumption in Asia are the increasing demand for electricity, the need to diversify the energy mix, and the pressure to reduce greenhouse gas emissions and air pollution.

Production of Pellet

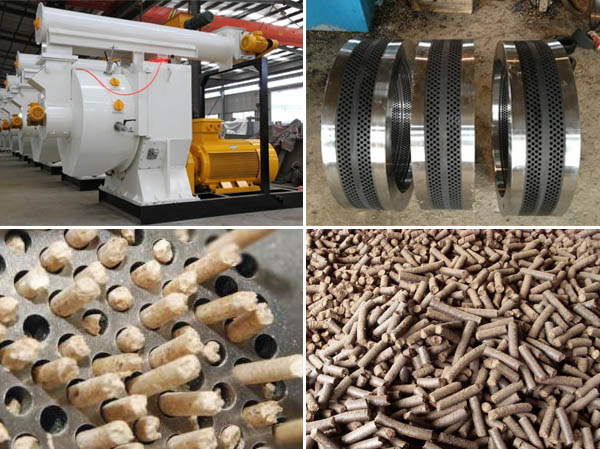

The production of pellet involves several steps, such as raw material collection, drying, grinding, conditioning, pelleting, cooling, screening, and packaging. The raw material for pellet production can be sourced from various sources, such as sawmills, forest harvests, agricultural residues, or industrial waste. The raw material is then dried to reduce its moisture content to below 10 per cent. The dried material is then ground to a uniform size of about 5 mm. The ground material is then conditioned with steam and additives to improve its binding and lubricating properties. The conditioned material is then fed to a pellet mill, where it is compressed through a die with holes of the desired size (normally 6 mm or 8 mm). The high pressure and temperature cause the lignin in the biomass to act as a natural glue that holds the pellet together. The pellets are then cooled to harden and stabilize their shape. The pellets are then screened to remove any fines or dust. The pellets are then packaged in bags or bulk for storage or transportation.

The production of pellet requires a lot of energy and equipment. According to a study by the U.S. Department of Energy, the energy consumption for pellet production ranges from 3.4 to 4.9 GJ/tonne, depending on the feedstock type and moisture content. The main energy inputs are electricity for grinding and pelleting, and natural gas or biomass for drying and conditioning. The main equipment for pellet production includes dryers, hammer mills, pellet mills, coolers, screeners, conveyors, and bagging machines.